2019- 10- 15

Bearings are high precision parts. As such, improper handling will lead to premature bearing failure. It should be taken care in handling bearings during installation.

1. Incorrectly sized shafts or housings

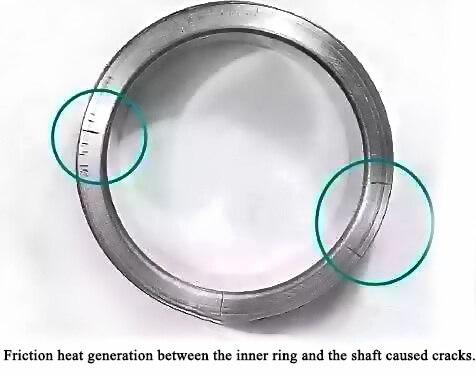

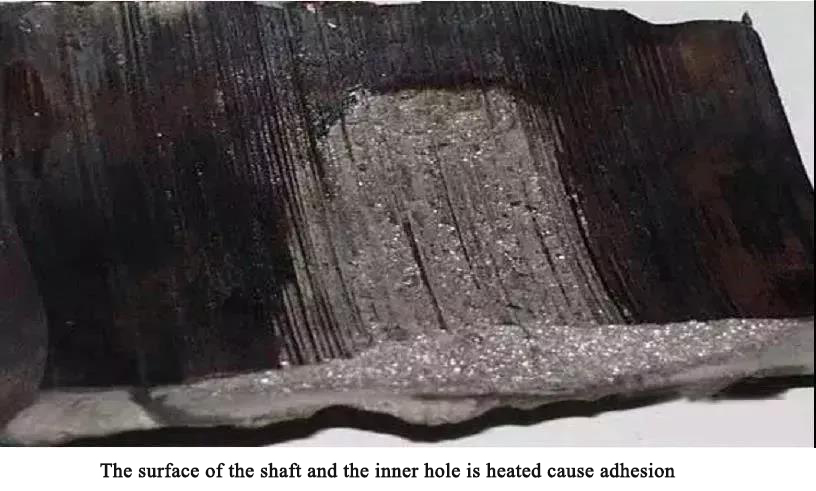

The shaft is too loose with the inner bore of the bearing

The loose fit of the shaft to the inner bore of the bearing will result in the slippage. Sliding friction will cause heat and damage the bearing.

2. Using brute force

Applying pressure or blows to the outer race) to mount bearings on the shaft.It damages the bearing raceways and the surface of the rolling elements, causing noise and premature damage to the bearings.

3. Heating temperature is too high

The inner hole of the bearing is heated by an acetylene spray gun,When the heating temperature exceeds 727°C (phase change temperature of the bearing steel), the metallographic structure inside the bearing steel changes. When the bearing is cooled, the bearing bore cannot be restored to its original size, usually larger than the size before heated.

These mistakes may caused the following: Denting, cracked rings, premature wear, early fatigue and eventually premature failure of the bearings.

The precise tools and procedure required to install a bearing vary with its size, type, speed, application and industry. Our experienced engineers will work with you through professional consultation and recommendations for proper mounting and dismounting to extend your machine uptime.

Having doubts about your the installation procedure for your bearings?

Click below to book a consultation time with one of our expert engineers to discuss about bearings installation and its maintenance processes.