2019- 06- 24

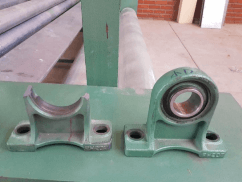

In the process of using, sometimes bearing damage will be encountered. Then, what it caused bearing damage? I've listed five reasons.

First, bearing long-term overload operation, continuous fatigue operation, coupled with the lack of corresponding maintenance, and rarely timely maintenance, or improper maintenance and equipment aging, etc. these are easy to cause bearing damage.

Second, the improper installation method caused bearing damage. Failure to follow the correct installation method in the installation process, improper installation or brutal installation will lead to bearing damage.

Third, the use of harsh environment, around the corrosive substances, these will shorten the service life of bearings. Dust and metal particles enter the inner part of the bearing, resulting in pollution; installation of the Working Environment is not clean, resulting in pollution and so on.

Fourth, the bearing was not properly lubricated. Poor lubrication is the main reason of premature damage for bearings include: short timely adding lubricants; the lubricant are filled in wrong place; the lubricating oil selects the situation improperly and so on.

Fifth, bearings’ low quality is also a factor in bearing damage. The selection of materials, processing technology and product structure design are all important that affect the quality of bearings. Poor quality will affect the service life seriously of bearings.

So how to prevent bearing damage? If you have interested in bearings, please pay attention to my next article, which will show details of avoid ways. Call us now to speak about your request for bearing, just do it.

You know how to find us.

vivivan@debtbearing.com www.debtbearing.com

DEBOT MACHINERY (BEARING) CO.,LTD