2025- 05- 09

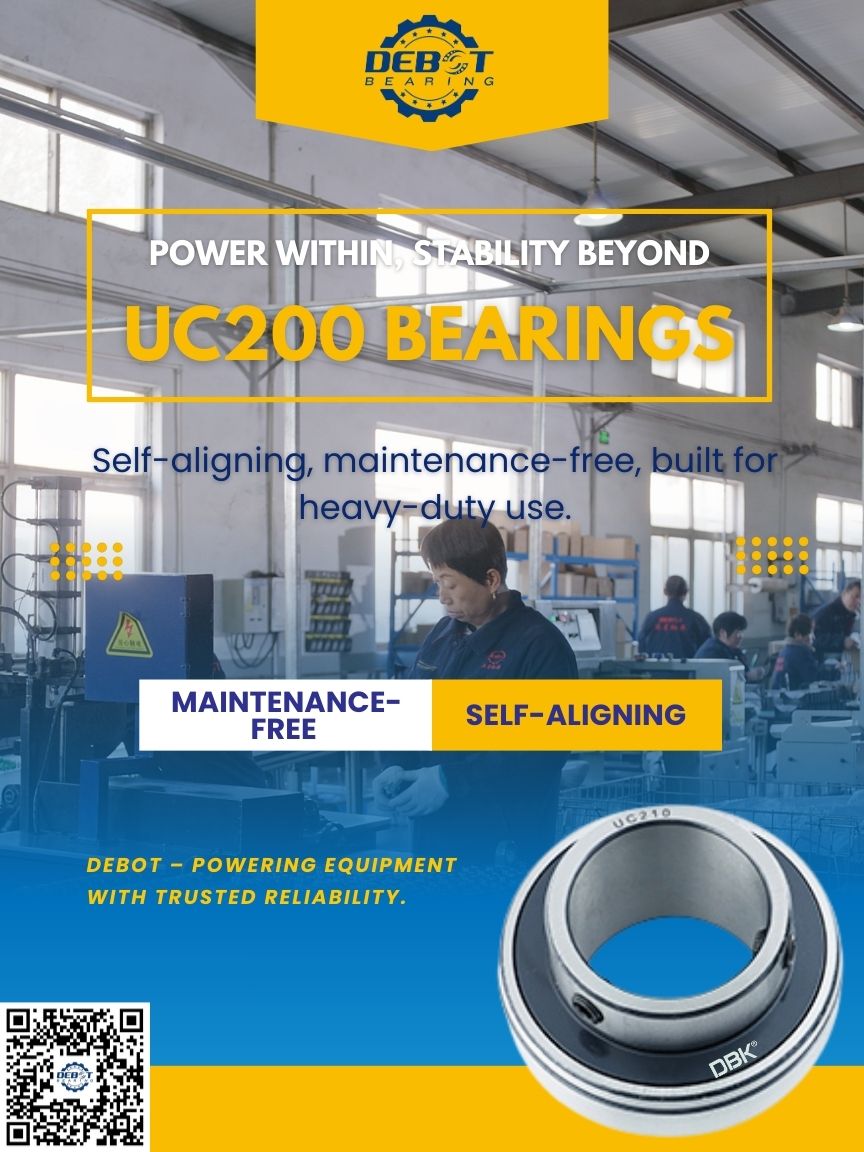

Bearings play a crucial role in machinery by supporting rotating components, reducing friction, and improving operational efficiency. Among the many bearing types, the UC200 series insert bearings stand out for their compact structure, easy installation, and strong adaptability—making them ideal for medium to low-speed equipment that requires simple mounting and regular maintenance.

The UC200 bearing belongs to the insert ball bearing unit family and is one of the most widely used types in various industries. It features an extended inner ring with set screws or other locking mechanisms, allowing it to be directly mounted on the shaft and paired with a bearing housing for easy replacement.

Key structural features include:

● Thick spherical outer race: Allows for self-alignment, compensating for minor shaft misalignment or housing deformation.

● Double-sealed design: Prevents dust and moisture ingress, suitable for dusty or outdoor environments.

● Set screw locking: Secure fit for shafts in machinery not frequently disassembled.

● Standardized dimensions: Compatible with various types of bearing housings.

The performance and service life of UC200 bearings depend heavily on the precision of their manufacturing process:

1. Material Selection

The inner and outer rings are typically made from high-carbon chromium bearing steel (e.g., GCr15), known for excellent hardness and wear resistance.

2. Turning

Precision turning ensures accurate geometry and fit for inner and outer ring surfaces.

3. Heat Treatment

Quenching and tempering processes enhance fatigue resistance and mechanical strength.

4. Grinding

Fine grinding of the raceways ensures high surface finish and roundness, enabling smooth rotation.

5. Assembly & Cleaning

Components such as rolling elements, cages, and seals are assembled and cleaned (often using ultrasonic cleaning) to eliminate contaminants.

6. Lubrication & Sealing

Bearings are filled with grease and sealed to extend service life and minimize maintenance needs.

Due to their durability and versatility, UC200 bearings are used across multiple industries:

● Agricultural Machinery: Suitable for dusty, muddy, or humid environments in harvesters, seeders, etc.

● Conveyor Systems: Widely used in logistics, port handling, and production lines.

● Ventilation and HVAC Systems: Performs reliably in moisture-prone or high-temperature settings.

● Textile & Light Industrial Machinery: Ensures stable, continuous operation.

● Food Processing Equipment: Stainless steel or anti-corrosive versions available for hygienic environments.

Advantage | Description |

Easy Installation | Set screw locking allows for quick mounting with minimal alignment. |

Self-Aligning Capability | Spherical outer ring compensates for misalignment or shaft deflection. |

Low Maintenance | Standardized design simplifies replacement and reduces downtime. |

Versatile Adaptability | Performs well in varied environments (humidity, dust, heat). |

Multiple Variants | Available in different shaft sizes and specifications. |

The UC200 series is a practical and cost-effective bearing solution in power transmission. Understanding its structure, production process, and performance advantages helps users make informed decisions during equipment design, maintenance, and procurement. As smart manufacturing continues to evolve, bearing standardization and modularization will keep enhancing equipment reliability across industries.

For more information about UC200 technical specifications, matching components, or customized solutions, please contact the DEBOT technical team.